DISCOVER THE NEW TYRE LABEL

EU TYRE LABELLING REGULATION 2020/740 - GENERAL INFO

This initiative is part of the 2030 Climate and Energy framework of European Union designed to improve the energy performance of products, buildings and services to reduce energy consumption at least 32.5 % until 2030 (CO2 emission compared to 1990)

Regulation (EC) No 1222/2009 first introduced the obligation of placing car and van tyres on the EU market with a sticker showing the label.

That regulation has been replaced by Regulation (EU) 2020/740 from 1 May 2021 onwards, when new requirements start applying. Under the new regulation, bus and truck tyres are also covered.

“Tyre energy labels provide a clear and common classification of tyres performance for rolling resistance, braking on wet surfaces and external noise. The labels help consumers make informed decisions when they are buying tyres as they can easily set their priority choice based on the 3 parameters:

- The energy efficiency class ranges from A (most efficient) to E (least efficient). A top class tyre has less rolling resistance and therefore requires less energy to move the vehicle. This translates into lower energy costs (fossil fuels or electricity).

- The wet grip class ranges as well from A (shorter braking distance on wet asphalt) to E (for truck).

- The external noise class ranges from the best (category "A") to the worst performance (category "C") and noise value in dB”

(Source: European Commission)

In addition to fuel efficiency, safety and noise emission, the Energy label reports:

- 3PMSF marking

- QR code to access to a public database where the label information is stored and accessible to all.

CAREFUL DRIVING WITH AWARENESS HELPS THE ENVIRONMENT AND SAFETY

Actual fuel savings and road safety heavily depend on drivers’ behaviour and correct tyre management and care:

- eco‐driving can significantly reduce fuel consumption

- tyre pressure needs to be regularly checked to optimize fuel efficiency and wet grip

- braking distances must always be respected

Link to the page of European Commission site dedicated to the new labelling for tyres

FOR ADDITIONAL INFO SEE ALSO

2030 climate & energy framework

Energy efficiency targets

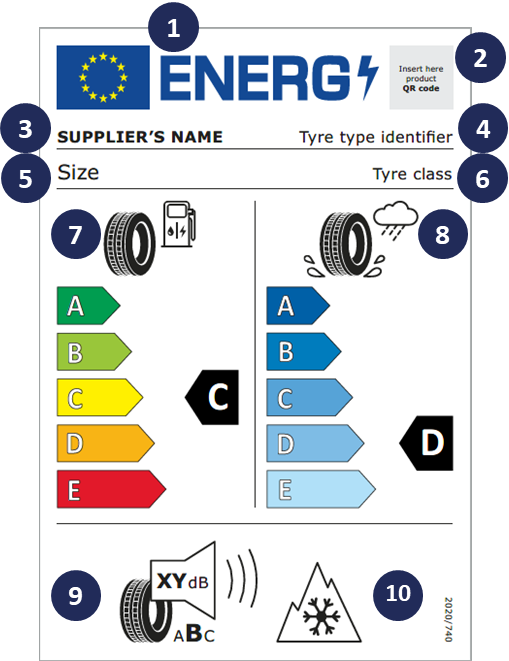

HOW TO READ THE LABEL

The future of your tyre starts with label understanding

- Label title name (“Energy”)

- QR code to access to EPREL database

- Trade name or trademark of the supplier

- Tyre type identifier

- Tyre size designation, load Capacity index and speed category symbol

- Tyre Class: i.e. C1, C2, or C3 (Truck and bus tyres)

- Fuel efficiency pictogram, scale and performance class

- Wet grip pictogram, scale and performance class

- Noise level indicated with the number of decibels accompanied by letters A, B or C

- Snow flake pictogram 3PMSF for tyres suitable for use in more severe winter conditions

Fuel efficiency pictogram, scale and performance class

FUEL EFFICIENCY with the tyre's rolling resistance.

Rolling Resistance is a force acting opposite to the travel direction when the tyre is rolling.

Considering that tyres contribute up to 20% of the overall fuel consumption for a car and up to 33% for a truck (for long haulage application), it is important to reach low Rolling Resistance values.

Let's understand how it works: due to the vehicle load, the tyre is deformed in the contact area with the road surface dissipating energy in form of heat. The higher deformations, the higher the rolling resistance and consequently more fuel consumption and CO2 emissions.

In the EU tyre Regulation label, rolling resistance is expressed in grades, ranging from A (best grading) to E (worst grading) for industrial vehicles and cars

Wet grip pictogram, scale and performance class

SAFETY associated to the tyre's wet grip.

Wet grip is one of the most important safety performances of a tyre. Excellent grip on wet means shorter braking distances when driving in rainy weather.

There are other important parameters which are relevant for safety but wet grip was chosen as the most representative situation in order to compare different tyres.

For truck the difference between each grade means an increase or decrease in stopping distance of roughly 2 and 3 meters when braking from 60 km/h to 20Km/h.

External rolling noise pictogram, value (expressed in db(A) and rounded to the nearest integer) and performance class

EXTERNAL NOISE LEVEL (given in decibels)

Traffic noise is a relevant environmental issue determined by several factors such as:

Traffic intensity - Vehicle type - Driving style - Tyre-Road interaction.

The value indicated in the label is not the internal that the driver will perceive while driving, but the external one, that is contributing to acoustic pollution.

It is expressed in decibel (dB) and split in 3 categories:

- A Class (Best Performance): at least 3dB less than the Limit Value of EU reg. 661/2009

- B Class: compliant with the Limit Value of EU reg 661/2009

- C Class (Worst Performance): compliant with Omologative Limits but over the Limit Value of EU reg. 661/2009.

Snow Grip Pictogram

TYRE FOR USE IN SEVERE SNOW CONDITIONS (3PMSF symbol)

The tyre bearing this symbol is specifically designed for use in severe snow conditions and can bear the symbol only after a specific test for the measurement of snow grip performances.

The pictogram known as ‘Alpine Symbol’ or ‘3 Peaks Mountain Snow Flake’ or (3PMSF) is also included on the tyre label of a tyre which satisfies the minimum snow grip index values set out in the 2020/740 regulation that provide also the testing method.

Many European countries are increasing the adoption of legislations that allow the vehicle circulation during winter season only to vehicle provided with tyres bearing Alpine symbol in some different conditions (roads, regions or periods)

EPREL database / Product Information sheet

(European Product Registry for Energy Labelling)

According to the EU label regulation 2020/740, tires sold in Europe must have an ENERGY LABEL and the related information must be registered on the EPREL.

Through the QR code displayed on the Label or Trademark and Tyre Type Identifier, consumers can access the public web portal and download:

- official EU Label values

- Product information sheet, which includes the designation data and grading for each Tyre Type Identifier

FAQ

Do all tyres fall under the scope of the Regulation?

The rules apply only to passenger car tyres (C1), light truck tyres (C2) and heavy duty vehicle tyres (C3).

The following categories are excluded from the scope:

Retreaded tyres

Professional Off Road tyres

Racing tyres

Studded tyres (studdable tyres if supplied without studs are covered)

Temporary –use spare tyres

Tyres designed to be fitted on vehicles registered for the first time before 1 October 1999

Tyres whose speed rating is less than 80 Km/h

Tyres whose nominal rim diameter does not exceed 254 mm or is 635 mm or more

What is rolling resistance (RR)?

RR is a force acting opposite to the travel direction if a tyre is rolling.

Due to the vehicle load, the tyre is deformed in the contact area with the road surface.

This deformation induces internal losses, same as a rubber ball falling down that does not rebound as high as it was launched.

Tyre RR can be expressed as a Force (Newton) or as a Coefficient (RRc).

The rolling resistance coefficient is defined as RR force (N) divided by the tyre load and commonly expressed in kN/N. The advantage of the coefficient is that it allows easier comparison of tyres designed to be fitted on different vehicles

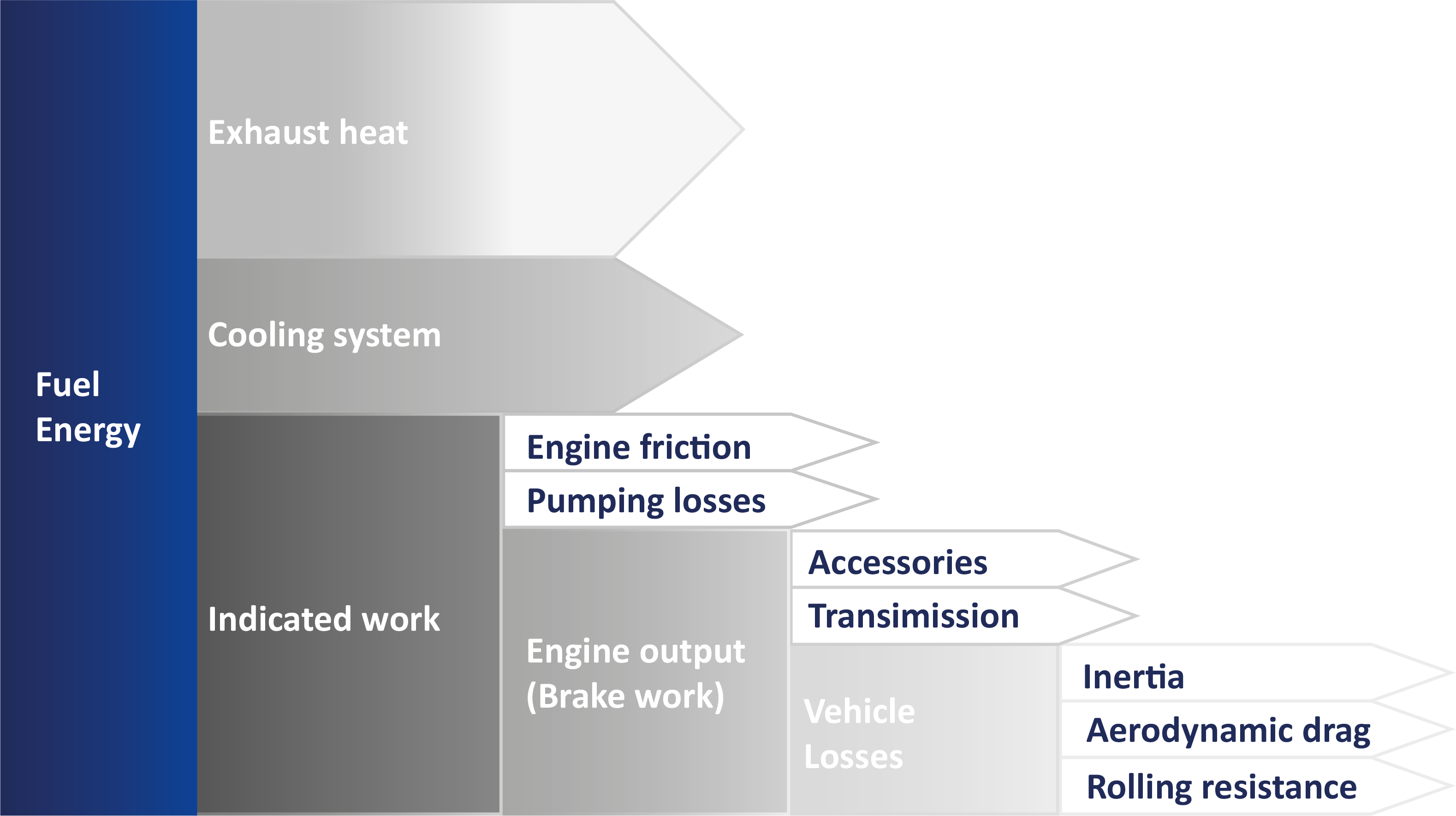

How does RR contribute to vehicle fuel consumption? What other factors contribute to fuel consumption?

The vehicle engine has to provide a force to compensate RR.

This consumes some fuel and so contributes to the vehicle fuel consumption.

As a rule of thumb, reducing RR by 10% decreases fuel consumption by 2% for a truck but it depends on the segment application

Many other factors contribute to vehicle fuel consumption:

Aerodynamics, vehicle weight, type of engine, auxiliary systems like air-condition, slope of the road, personal driving style, tyre pressure level, accelerations or general traffic conditions.

What is the relationship between wet grip and RR?

There are many different tyre characteristics that affect tyre RR. Adjusting the RR can be done by modifying certain of these parameters, but some of them can also have a negative impact on wet grip.

The tyre development engineer must use the right tools in the right amount to achieve the optimum balance for RR and wet grip.

If tyre RR limits are lowered too far, the required tradeoffs could adversely affect the wet grip performance.

How is the measured wet grip linked to road safety especially when it comes to different road conditions (dry, wet, snowy, icy)?

Wet grip refers to the safety performance of tyres:

it reflects the capacity of a tyre to brake on a wet road.

There are other parameters which are relevant for safety (e.g. road holding ability, directional control, deceleration ability on wet and dry surfaces at higher speed) but wet grip was chosen as the most representative situation of reduced adherence in Europe.

As well the performance during snowy condition are monitored by 3 peak mountain snow flake marking test

What is the difference between limit and grading?

A limit is the minimum acceptable performance level for a tyre to be authorized on the European market;

A grading will give the performance level under defined testing conditions of the tyre on its rolling resistance, its braking on wet surface and its external rolling noise.

How is the compliance with the tyre label regulation secured?

It is the responsibility of the national market surveillance authorities to assess the conformity of the declared grading values and The Commission shall encourage and support cooperation and the exchange of information on market surveillance relating to the labelling of tyres between the authorities of the Member States that are responsible for market surveillance.

The procedures for verification are detailed under Annex VI of the regulation

Why are „POR“-tyres excluded from labelling?

POR tyres are out of the scope of reg 2020/740 because are tyres specially designed to reach exceptional adherence performances in poor conditions and in all terrain, which does not allow them to fulfil regulatory thresholds and significant grading levels.

Are there any plans to include retreads?

There are plans to introduce labelling requirements to retreads; by 26 June 2022, the Commission shall adopt delegated acts in accordance in order to supplement the Regulation 2020/740 by introducing new information requirements for re‐treaded tyres in the Annexes, provided that a suitable testing method is available.

Are there any plans to issue an EU-fuel savings calculator showing the impact of differently labelled tyres on fuel consumption/fuel spending?

The European Commission shall start work to develop a harmonized fuel saving calculator which could eventually be posted on each manufacturers’ websites, to calculate fuel savings and compare products